Leading Industrial Manufacturer Reduces Lead Time & Dramatically Improves Productivity

Challenge

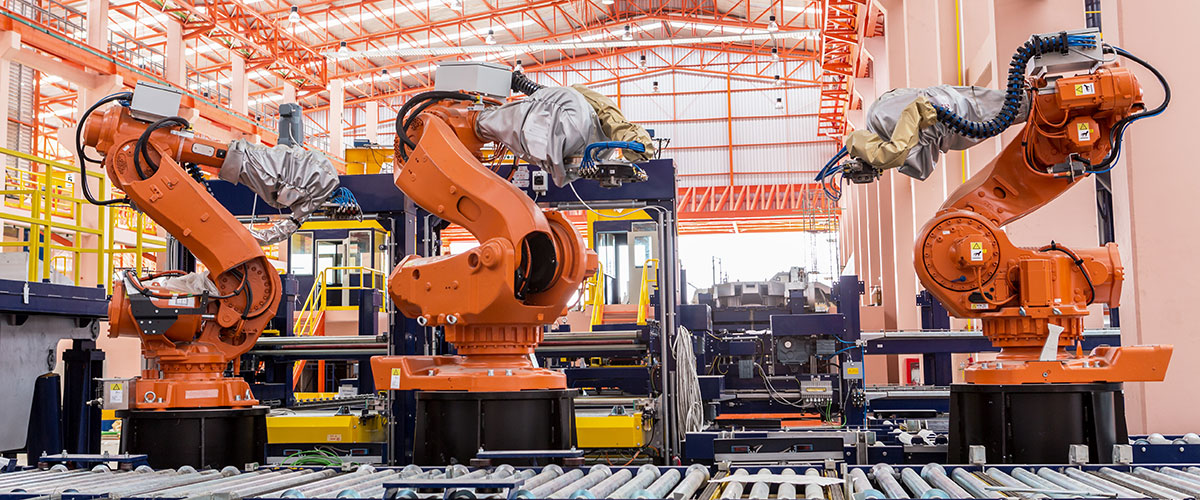

This industrial manufacturer struggled to meet their delivery schedule with a major customer. They needed to optimize the flow and layout of their production processes to increase throughput and improve efficiency.

Opportunity

We knew that, upon closer examination of their facilities, we could gather the right information necessary to draft up a Lean Transformation roadmap that would help them create the high-performance culture they needed to deliver the immediate results they desired, while also giving them the tools and systems they needed to drive sustained, profitable growth.

Our Response

Within a week from the first call, we were walking their facilities, conducting rapid plant analysis, identifying the organization’s root problems. Once we had all the data necessary, we drafted up a Lean Transformation roadmap and began conducting several Kaizen events. One event involved the ratchet assembly area, and two events targeted improving forecasting, scheduling, and replenishment processes relative to a major customer.

Results

The company improved productivity of flagship product by 37%. They made significant improvements to their safety stock, enabling them to build products a lot faster than they had before. They also reduced lead time from 55 days to 7, resulting in their major customer awarding them a “Supplier of the Year” award.